Maximizing Efficiency: The Critical Role of Fasteners in Agricultural Machinery

Sep 22,2025

Maximizing Efficiency: The Critical Role of Fasteners in Agricultural Machinery

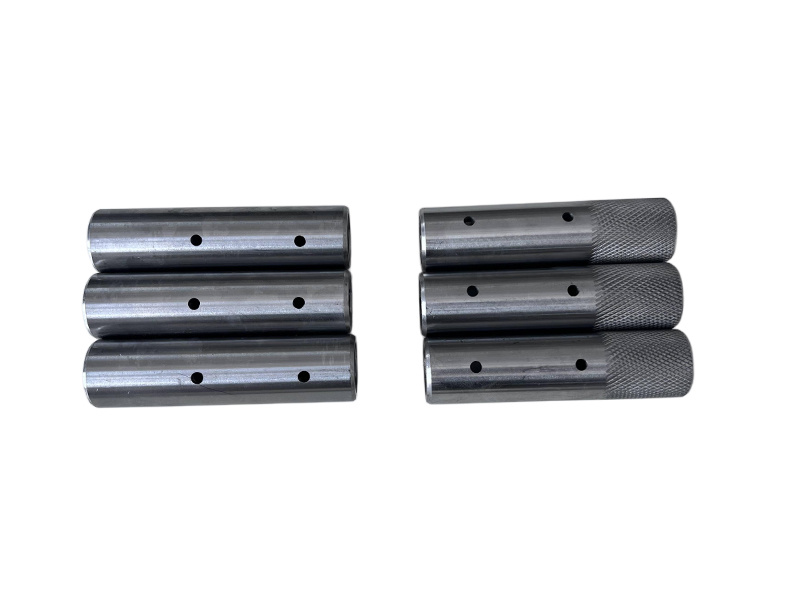

The agricultural sector is constantly evolving, with an emphasis on innovation and efficiency to meet the demands of a growing population. Among the unsung heroes of this sector are fasteners, small yet crucial components that play a vital role in the functionality and durability of agricultural machinery. Understandin

Maximizing Efficiency: The Critical Role of Fasteners in Agricultural Machinery

The agricultural sector is constantly evolving, with an emphasis on innovation and efficiency to meet the demands of a growing population. Among the unsung heroes of this sector are fasteners, small yet crucial components that play a vital role in the functionality and durability of agricultural machinery. Understanding the role of fasteners can lead to maximizing efficiency in operations and ensuring the longevity of machines.

The Importance of Fasteners in Agricultural Machinery

Fasteners are more than just parts; they are essential for the assembly and integrity of agricultural machinery. They hold various components together, ensuring that machines can withstand the rigors of operation in diverse agricultural environments. Here, we explore why fasteners are critical:

1. Structural Integrity

Fasteners provide the necessary strength to maintain the structural integrity of machinery, preventing breakdowns that can lead to costly downtime. The correct fastener choice ensures that components remain securely attached, even under extreme operational conditions.

2. Vibration Resistance

Agricultural machinery often operates in environments characterized by high vibration levels. Fasteners designed for vibration resistance, such as locking nuts and specialized washers, are essential for preventing loosening and maintaining tight connections over time.

3. Corrosion Resistance

Agricultural machines are frequently exposed to moisture, chemicals, and other corrosive elements. Selecting fasteners made from corrosion-resistant materials, such as stainless steel or coated options, can prolong the lifespan of machinery and reduce maintenance costs.

Types of Fasteners Commonly Used in Agricultural Machinery

Understanding the different types of fasteners and their specific applications can greatly enhance the efficiency and reliability of agricultural machinery. Here are some commonly used fasteners:

1. Bolts

Bolts are heavy-duty fasteners used for securing components in agricultural machines. They come in various grades and sizes, allowing for versatility in applications. The use of high-strength bolts is particularly critical in high-stress areas of machinery.

2. Nuts

Nuts pair with bolts to create secure fastening systems. Locking nuts are particularly important in agricultural machinery, as they provide extra resistance against loosening due to vibration.

3. Washers

Washers are essential for distributing load and preventing damage to the surface of the material being fastened. They also enhance the effectiveness of the bolt and nut system by improving torque.

4. Screws

Screws are often used in lighter applications where components need to be secured without the need for a nut. They are widely used in electronic components of agricultural machinery.

5. Rivets

Rivets are permanent fasteners ideal for situations where components must be joined without the possibility of disassembly. They are commonly used in the fabrication of agricultural machinery frames and casings.

Best Practices for Selecting Fasteners in Agricultural Machinery

Choosing the right fastener is crucial for the efficiency and longevity of agricultural machinery. Here are some best practices to guide you:

1. Assess the Environment

The operating environment plays a significant role in fastener selection. Consider factors such as exposure to moisture, chemicals, and temperature variations. Selecting fasteners that can withstand these conditions will improve performance and reduce failure rates.

2. Match Fastener Material with Application

Different materials offer varying levels of strength and resistance. For instance, stainless steel is excellent for corrosion resistance, while carbon steel provides strength for heavy-duty applications. Always match the fastener material to the specific needs of the machinery.

3. Pay Attention to Torque Specifications

Each type of fastener has specific torque requirements for optimal performance. Over-tightening can lead to stripping, while under-tightening can result in loosening. Always refer to manufacturer specifications for proper torque settings.

4. Regular Maintenance and Inspection

Routine inspection of fasteners is essential in maintaining agricultural machinery. Look for signs of wear, corrosion, or loosening, and replace fasteners as necessary to prevent costly breakdowns.

The Role of Fasteners in Enhancing Agricultural Machinery Performance

Fasteners contribute to the overall performance of agricultural machinery in several ways. Here’s how they make a difference:

1. Improved Reliability

When fasteners are correctly chosen and maintained, they enhance the reliability of machinery. This reliability translates into fewer breakdowns and increased operational uptime, allowing farmers to focus on productivity.

2. Enhanced Safety

Fasteners that are properly secured are vital for the safety of operators and bystanders. Loose or failing fasteners can lead to catastrophic machinery failures, resulting in injuries. Investing in high-quality fasteners and conducting regular checks can significantly improve safety.

3. Increased Efficiency

Efficient machinery translates to higher productivity. Fasteners that maintain the integrity of machinery ensure it operates at optimal levels, reducing fuel consumption and increasing output.

Innovations in Fastener Technology for Agriculture

The agricultural industry is continuously evolving, and so is fastener technology. Here are some recent innovations that can further enhance machinery efficiency:

1. Self-Locking Fasteners

Self-locking fasteners are designed to prevent unintended loosening, effectively addressing one of the most common issues associated with fasteners in agricultural machinery. These can significantly reduce maintenance efforts and improve uptime.

2. Advanced Coatings

The development of advanced coatings provides enhanced corrosion resistance and durability. These coatings are designed to withstand harsh agricultural environments, extending the lifespan of fasteners significantly.

3. Lightweight Materials

With a push for more fuel-efficient machinery, manufacturers are exploring lightweight materials for fasteners. These innovations help reduce overall machine weight without compromising strength, resulting in better fuel efficiency and performance.

Common Mistakes to Avoid When Using Fasteners in Agricultural Machinery

To maximize the efficiency of agricultural machinery, it’s important to avoid common mistakes associated with fastener use:

1. Using Incorrect Fastener Types

Utilizing the wrong type of fastener can lead to mechanical failures. Always ensure the fastener is suitable for the specific application, considering stress levels and environmental factors.

2. Neglecting Maintenance

Ignoring the importance of routine maintenance can have dire consequences. Regular checks and replacements of fasteners are necessary to maintain machinery integrity.

3. Overlooking Manufacturer Specifications

Failing to adhere to manufacturer specifications for torque settings and materials can lead to machinery inefficiencies. Always consult the equipment’s manual for guidance.

Frequently Asked Questions (FAQs)

1. What types of fasteners are best for agricultural machinery?

Choosing fasteners made from high-strength, corrosion-resistant materials like stainless steel is ideal for agricultural machinery.

2. How often should I inspect fasteners on my machinery?

Regular inspections should be conducted at least once a month or before each major use, especially in high-stress environments.

3. Can I use regular nuts and bolts for agricultural equipment?

It’s best to use fasteners specifically designed for agricultural applications to ensure durability and performance under heavy loads.

4. What should I look for when purchasing fasteners?

Consider factors such as material strength, corrosion resistance, and compatibility with your machinery.

5. Are self-locking fasteners worth the investment?

Yes, self-locking fasteners can greatly reduce maintenance needs and enhance machinery reliability, making them a valuable investment.

Conclusion

Fasteners are integral to the efficiency and performance of agricultural machinery. Their proper selection, application, and maintenance can significantly impact productivity and safety in agricultural operations. By understanding the role of fasteners and implementing best practices, farmers and machinery operators can ensure their equipment performs optimally, ultimately maximizing efficiency and output. Investing time and resources into the right fasteners is an essential step toward achieving greater success in the agricultural industry.

TAG:

Recent News

Mastering Agricultural Machinery: A Deep Dive into Engine Speed Control Shaft Mechanics

Mastering Agricultural Machinery: Understanding Engine Speed Control Shaft

Table of Contents

1. Introduction to Engine Speed Control Shaft in Agricultural Machinery

2. Importance of Engine Speed Control Shaft in Agricultural Machinery

3. How Engine Speed Control Shaft Works

4. Types of Engine Speed Control Shafts

4.1. Mechanical Control Shafts

4.2. Electronic Control Shafts

5. Common Issues with E