A Comprehensive Guide to Machinery Components Production: Types and Models

Sep 05,2025

Machinery components production is a crucial aspect of the manufacturing industry, supplying essential parts that facilitate the operation of various machines across different sectors. These components are designed to meet specific performance criteria, ensuring reliability and efficiency. The production process typically involves a combination of advanced manufacturing techniques, including machi

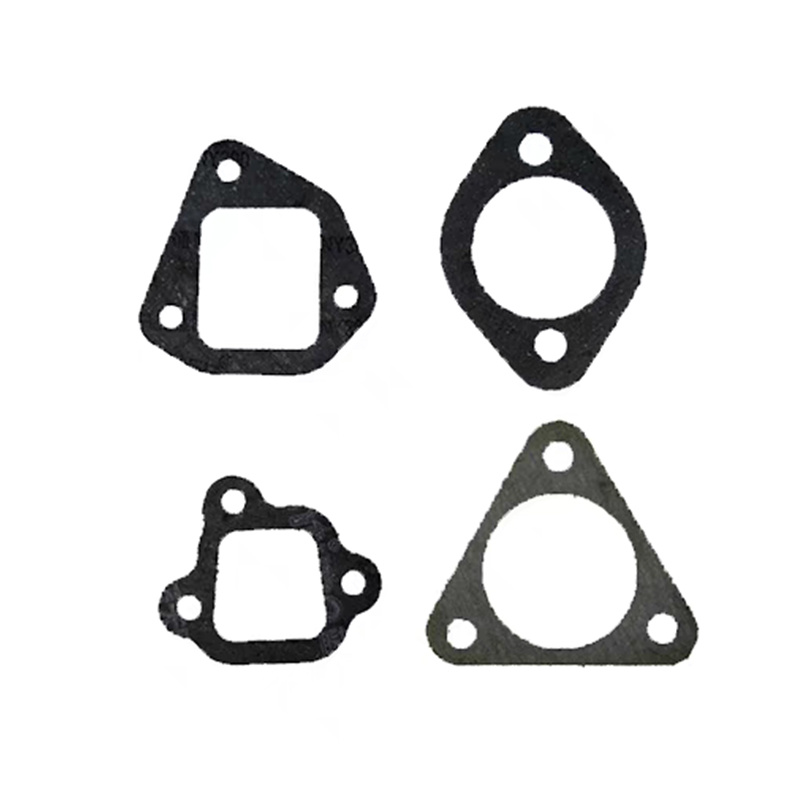

Machinery components production is a crucial aspect of the manufacturing industry, supplying essential parts that facilitate the operation of various machines across different sectors. These components are designed to meet specific performance criteria, ensuring reliability and efficiency. The production process typically involves a combination of advanced manufacturing techniques, including machining, casting, and additive manufacturing.

One of the primary types of machinery components is gears, which are vital for transferring motion and torque between different machine parts. Gears come in various models, such as spur gears, bevel gears, and worm gears, each serving unique purposes. Spur gears are widely used for their simplicity and efficiency in transmitting power between parallel shafts. Bevel gears, on the other hand, are designed for shafts that intersect at an angle, making them ideal for applications requiring changes in direction. Worm gears offer a high reduction ratio, making them suitable for applications where precise speed control is necessary.

Another significant category of machinery components is bearings, which reduce friction between moving parts and support loads. The most common types of bearings include ball bearings, roller bearings, and thrust bearings. Ball bearings are versatile and used in several applications due to their ability to handle both radial and axial loads. Roller bearings have a larger contact area, allowing them to support heavier loads while maintaining low friction. Thrust bearings, specifically designed to handle axial loads, are essential in applications like automotive transmissions and rotating equipment.

Fasteners also play a vital role in machinery components production. These include bolts, nuts, screws, and washers, which are used to secure various machine parts together. The production of fasteners often involves processes like cold heading and thread rolling, ensuring that they meet stringent quality standards.

In recent years, the advent of additive manufacturing, commonly known as 3D printing, has revolutionized machinery components production. This innovative technology allows for the creation of complex geometries that traditional methods cannot achieve. Models produced through additive manufacturing include custom brackets, housings, and even some functional parts, offering manufacturers unprecedented design flexibility.

In conclusion, machinery components production encompasses a wide range of types and models, from gears and bearings to fasteners and 3D-printed parts. Each component plays a pivotal role in ensuring the functionality and efficiency of machines across various industries. As technology continues to evolve, we can expect further advancements in the production processes and designs of these essential components, ultimately enhancing manufacturing capabilities and driving innovation. Understanding these components is essential for anyone involved in the manufacturing sector, highlighting the importance of precision and quality in machinery components production.

One of the primary types of machinery components is gears, which are vital for transferring motion and torque between different machine parts. Gears come in various models, such as spur gears, bevel gears, and worm gears, each serving unique purposes. Spur gears are widely used for their simplicity and efficiency in transmitting power between parallel shafts. Bevel gears, on the other hand, are designed for shafts that intersect at an angle, making them ideal for applications requiring changes in direction. Worm gears offer a high reduction ratio, making them suitable for applications where precise speed control is necessary.

Another significant category of machinery components is bearings, which reduce friction between moving parts and support loads. The most common types of bearings include ball bearings, roller bearings, and thrust bearings. Ball bearings are versatile and used in several applications due to their ability to handle both radial and axial loads. Roller bearings have a larger contact area, allowing them to support heavier loads while maintaining low friction. Thrust bearings, specifically designed to handle axial loads, are essential in applications like automotive transmissions and rotating equipment.

Fasteners also play a vital role in machinery components production. These include bolts, nuts, screws, and washers, which are used to secure various machine parts together. The production of fasteners often involves processes like cold heading and thread rolling, ensuring that they meet stringent quality standards.

In recent years, the advent of additive manufacturing, commonly known as 3D printing, has revolutionized machinery components production. This innovative technology allows for the creation of complex geometries that traditional methods cannot achieve. Models produced through additive manufacturing include custom brackets, housings, and even some functional parts, offering manufacturers unprecedented design flexibility.

In conclusion, machinery components production encompasses a wide range of types and models, from gears and bearings to fasteners and 3D-printed parts. Each component plays a pivotal role in ensuring the functionality and efficiency of machines across various industries. As technology continues to evolve, we can expect further advancements in the production processes and designs of these essential components, ultimately enhancing manufacturing capabilities and driving innovation. Understanding these components is essential for anyone involved in the manufacturing sector, highlighting the importance of precision and quality in machinery components production.

TAG:

Previous

Recent News

Mastering Agricultural Machinery: A Deep Dive into Engine Speed Control Shaft Mechanics

Mastering Agricultural Machinery: Understanding Engine Speed Control Shaft

Table of Contents

1. Introduction to Engine Speed Control Shaft in Agricultural Machinery

2. Importance of Engine Speed Control Shaft in Agricultural Machinery

3. How Engine Speed Control Shaft Works

4. Types of Engine Speed Control Shafts

4.1. Mechanical Control Shafts

4.2. Electronic Control Shafts

5. Common Issues with E