Contact Us

Nanpangkou Village, Gaoyang County, Baoding City, Hebei Province

Rocker arm

Products Category

Tag list

Product Detail

The structural composition of a single cylinder engine

Cylinder block: The cylinder block is the main part of the engine, which forms the combustion chamber inside and provides space for the piston to move.

Piston: The piston performs reciprocating motion inside the cylinder and is connected to the crankshaft through a connecting rod, converting the pressure of the gas into the rotational torque of the crankshaft.

Crankshaft: The crankshaft converts the reciprocating motion of the piston into rotational motion and is a key component for the engine to output power.

Cylinder head: The cylinder head is installed on the cylinder block, forming a combustion chamber together with the top of the piston, and is equipped with components such as intake valves, exhaust valves, spark plugs, etc.

Valve mechanism: including intake valve, exhaust valve, camshaft and other components, responsible for controlling the intake and exhaust process of the cylinder.

Fuel supply system: responsible for injecting fuel into the cylinder in an appropriate proportion and manner, mixing with air to form a combustible mixture.

Ignition system: In gasoline engines, the ignition system is responsible for igniting the combustible mixture at the appropriate time, generating explosive force to drive the piston movement.

Lubrication system: provides lubricating oil for various moving parts of the engine, reducing wear and frictional resistance.

Cooling system: It removes the heat generated by the engine through the circulation of coolant, keeping the engine operating within a suitable temperature range.

The rocker arm spacer is an essential engine component designed to provide proper alignment and stability for rocker arms during operation. Crafted from premium alloy steel or aluminum materials, the rocker arm spacer ensures precise spacing, reduces wear, and enhances the overall performance of the valve train system. Its reliable structure helps maintain accurate valve movement, which is critical for improving engine efficiency and longevity.

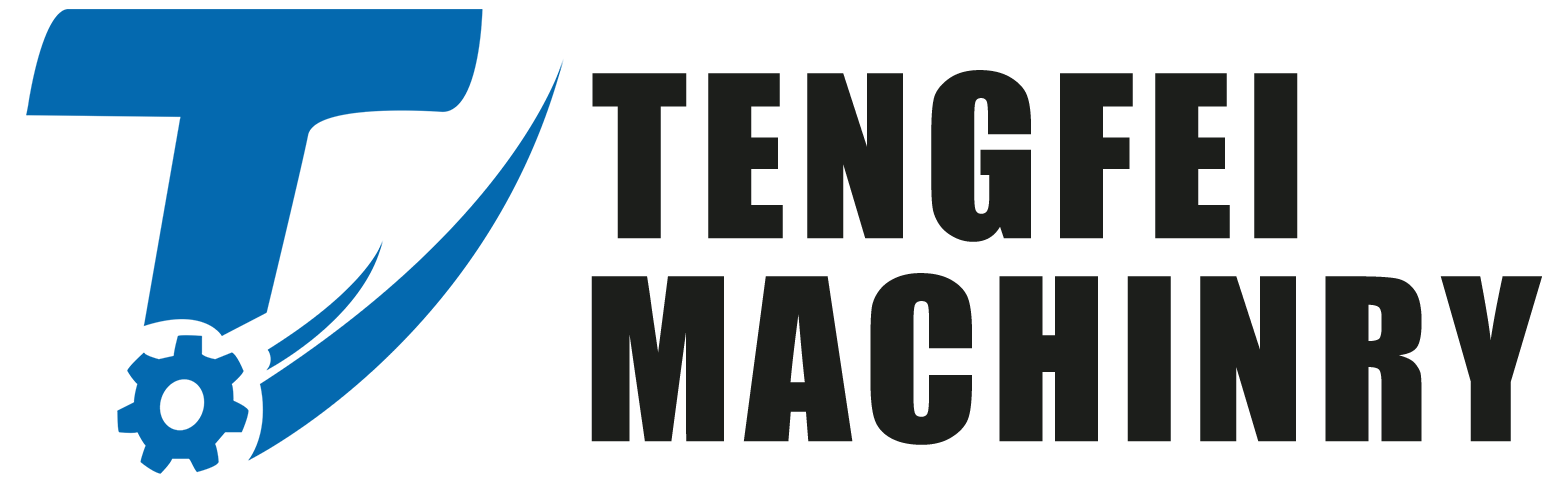

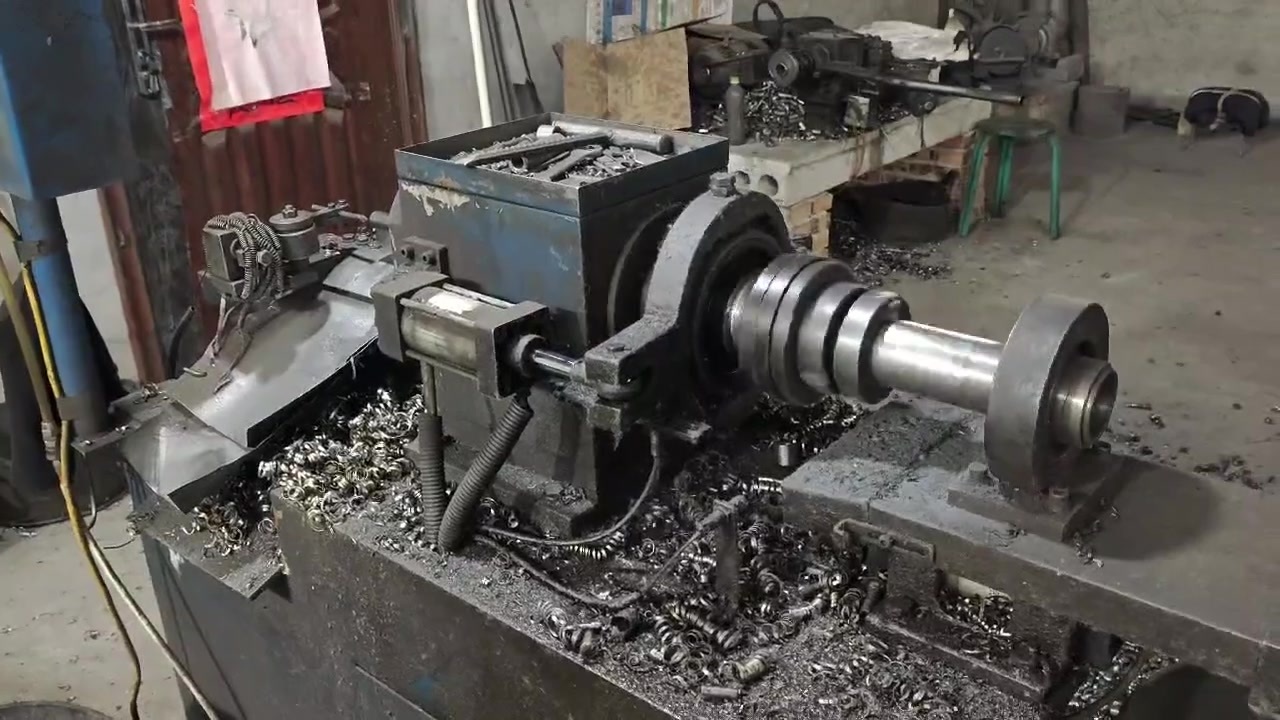

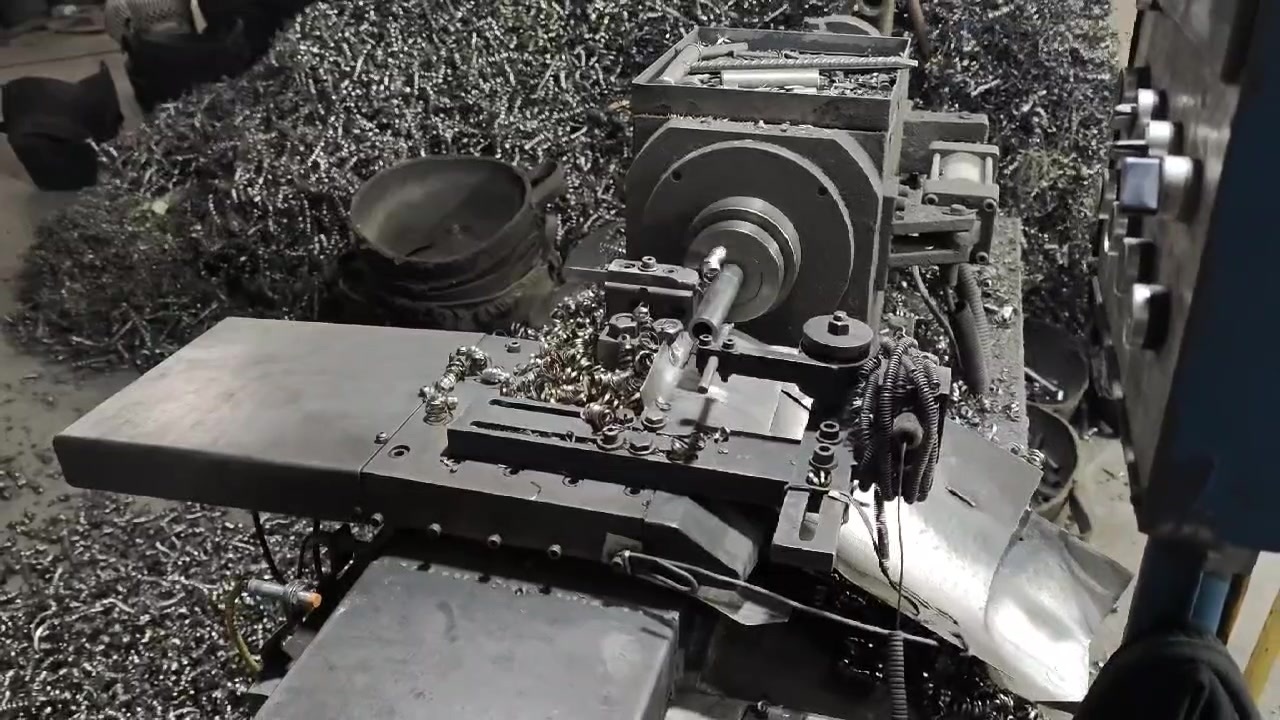

Engineers and mechanics value the rocker arm spacer for its durability and precision. Manufactured with advanced machining processes, it guarantees consistent thickness and surface finish to achieve optimal clearance between rocker arms. This reduces friction, minimizes vibration, and ensures smoother operation under high-speed and high-load conditions, making it suitable for automotive, motorcycle, and industrial engines.

Our rocker arm spacer is designed to resist deformation, heat, and corrosion, even under extreme operating environments. Its robust design allows it to withstand continuous pressure cycles while maintaining stable performance. Easy to install and compatible with a wide range of engine models, it provides a cost-effective solution for maintenance, repair, and engine upgrades.

Choosing our rocker arm spacer means investing in a component that supports long-term reliability and peak engine performance. With superior quality, precise engineering, and proven durability, this product is an ideal choice for manufacturers, repair professionals, and enthusiasts who demand dependable engine parts for maximum efficiency and stability.

ABOUT US

Gaoyang County Tengfei Machinery Factory has advanced machinery and equipment and a high-quality workforce, committed to scientific research and development, continuous innovation, strict testing of product quality, and control of production costs.The main products of Hebei Gaoyang Tengfei Machinery Factory include various screws, speed control shafts, rocker arm shafts, rocker arms, rocker arm seats, rocker arm assemblies, pressure reducer assemblies and other agricultural machinery parts, as well as pistons, piston pins, piston rings and other multi-cylinder machine series products。

Years of industry experience have accumulated profound professional knowledge of solutions

The factory covers an area and produces over 8 million units of products annually, which are exported to more than 20 countries.

Complete product specifications,Customer satisfaction with our products.

The product quality meets the national standards, but it can also be processed and customized according to customer requirements.

PHOTO GALLERY

Previous:

Next:

Online inquiry

We will contact you within one working day. Please pay attention to your email.