Unlocking Efficiency: The Importance of OHV Rocker Assembly in Modern Agriculture

Aug 04,2025

Unlocking Efficiency: The Importance of OHV Rocker Assembly in Modern Agriculture

Table of Contents

1. Introduction

2. Understanding OHV Rocker Assembly

3. Benefits of OHV Rocker Assembly in Agriculture

4. Mechanical Design and Features of OHV Rocker Assemblies

5. Impact on Modern Farming Techniques

6. Choosing the Right OHV Rocker Assembly for Your Machinery

7. Ma

Unlocking Efficiency: The Importance of OHV Rocker Assembly in Modern Agriculture

Table of Contents

- 1. Introduction

- 2. Understanding OHV Rocker Assembly

- 3. Benefits of OHV Rocker Assembly in Agriculture

- 4. Mechanical Design and Features of OHV Rocker Assemblies

- 5. Impact on Modern Farming Techniques

- 6. Choosing the Right OHV Rocker Assembly for Your Machinery

- 7. Maintenance and Care of OHV Rocker Assemblies

- 8. The Future of OHV Rocker Assembly in Agriculture

- 9. FAQs

- 10. Conclusion

1. Introduction

In the evolving landscape of modern agriculture, efficiency is the name of the game. With ever-increasing demands for food production, farmers need reliable machinery that can perform optimally under varying conditions. One of the key components that contribute significantly to the efficiency of agricultural machinery is the **Overhead Valve (OHV) rocker assembly**. This article delves into the critical role of the OHV rocker assembly and how it enhances operational efficiency in modern farming.

2. Understanding OHV Rocker Assembly

The OHV rocker assembly is an integral part of modern internal combustion engines found in agricultural machinery. It serves as a bridge between the camshaft and the engine's valves, ensuring precise timing and operation. Understanding its functionality can shed light on its importance.

What is OHV Technology?

OHV technology refers to the overhead valve design in engine configurations. This design places the valves in the cylinder head, allowing for more efficient airflow and combustion. The rocker assembly manipulates these valves, facilitating their opening and closing in sync with the engine’s operation.

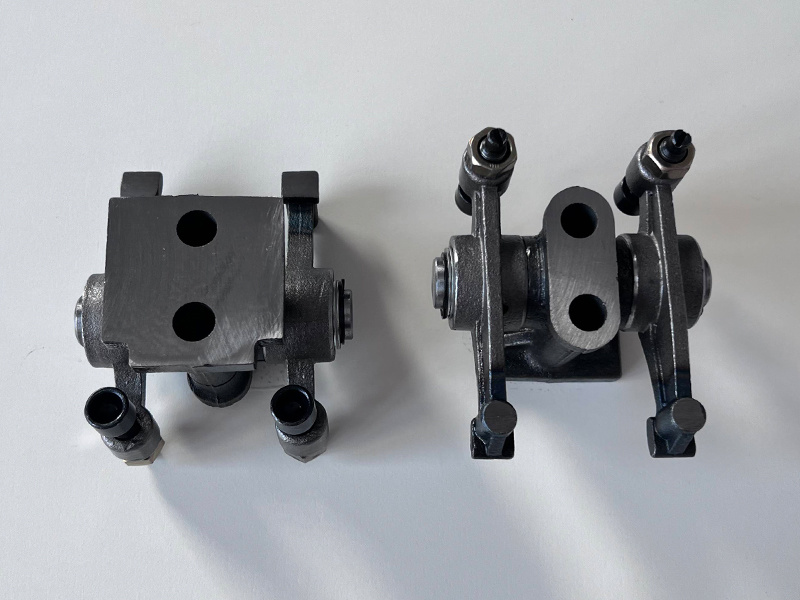

Components of OHV Rocker Assembly

The OHV rocker assembly comprises several critical components, including:

- **Rocker Arms**: These levers convert the rotational motion of the camshaft into linear motion that opens and closes the valves.

- **Push Rods**: They transfer motion from the camshaft to the rocker arms.

- **Camshaft**: This component controls the timing of valve openings and closings.

- **Valves**: Responsible for the intake of air/fuel mixture and the exhaust of combustion gases.

3. Benefits of OHV Rocker Assembly in Agriculture

The OHV rocker assembly offers numerous benefits that significantly impact agricultural efficiency:

Enhanced Engine Performance

With precise timing and control, OHV rocker assemblies contribute to better engine performance. Improved combustion efficiency leads to increased power output, allowing machinery to handle heavier loads and operate more effectively across various terrains.

Reduced Fuel Consumption

Efficiency translates to savings, particularly in fuel consumption. An optimized OHV rocker assembly ensures that the engine runs smoothly, reducing fuel wastage and lowering operational costs for farmers.

Lower Emissions

As environmental regulations tighten, the agricultural sector must adapt. OHV rocker assemblies facilitate cleaner combustion, helping to reduce harmful emissions from machinery. This is essential for sustainable farming practices.

Minimized Downtime

Well-designed rocker assemblies are less prone to failures, which means reduced downtime for maintenance and repairs. This reliability is crucial for farmers who depend on their machinery for timely operations.

4. Mechanical Design and Features of OHV Rocker Assemblies

The mechanical design of OHV rocker assemblies plays a crucial role in their efficiency. Understanding these features can help in selecting the right assembly for specific agricultural applications.

Durable Materials

Quality materials used in the construction of rocker assemblies enhance durability. High-grade alloys and composites withstand high temperatures and pressures, ensuring longevity and reliable performance.

Precision Engineering

Precision engineering techniques are employed to ensure that every component of the rocker assembly fits perfectly, reducing friction and wear. This precision translates to better performance and lower maintenance requirements.

Adjustability

Many modern OHV rocker assemblies offer adjustability, allowing farmers to fine-tune the valve lift and timing according to their specific needs. This customization is essential for optimizing performance based on different crops and field conditions.

5. Impact on Modern Farming Techniques

The integration of OHV rocker assemblies into agricultural machinery has transformed farming techniques in various ways.

Increased Agricultural Productivity

With enhanced engine performance and reduced downtime, farmers can achieve higher productivity levels. This means more efficient planting, harvesting, and overall crop management.

Adaptability to Advanced Technologies

The design of OHV rocker assemblies facilitates the integration of advanced technologies such as precision farming and automation. This adaptability enables farmers to leverage data-driven insights, making informed decisions that boost yield.

Improved Field Operations

Reliable machinery equipped with efficient OHV rocker assemblies allows for smoother field operations, reducing the risk of equipment failure during critical farming activities.

6. Choosing the Right OHV Rocker Assembly for Your Machinery

Selecting the appropriate OHV rocker assembly for agricultural machinery involves several considerations:

Compatibility with Engine Type

Ensure that the rocker assembly you choose is compatible with your engine type. Different engines may have varying requirements in terms of valve lift and timing.

Performance Specifications

Evaluate the performance specifications of the rocker assembly. Look for features that improve efficiency, such as low friction designs and adjustability.

Brand Reputation

Opt for reputable manufacturers known for high-quality products in the agricultural sector. Brand reputation can be an indication of durability and performance.

7. Maintenance and Care of OHV Rocker Assemblies

Proper maintenance is crucial to ensuring the longevity and efficiency of OHV rocker assemblies.

Regular Inspections

Conduct regular inspections to check for any signs of wear and tear. This proactive approach can help identify potential issues before they escalate.

Lubrication

Ensure that the rocker assembly is adequately lubricated to reduce friction and heat buildup. This maintenance practice is essential for optimal performance.

Timely Replacement of Worn Parts

Replace any worn or damaged components promptly to maintain the efficiency of the rocker assembly. Neglecting this can lead to increased downtime and costly repairs.

8. The Future of OHV Rocker Assembly in Agriculture

As technology continues to advance, the future of OHV rocker assemblies in agriculture looks promising.

Integration with Smart Farming Technologies

The evolution of smart farming technologies will lead to more sophisticated designs for OHV rocker assemblies, enhancing their efficiency further. Automation and data analytics will drive the optimization of performance.

Emphasis on Sustainability

With an increasing focus on sustainable agricultural practices, innovations in OHV rocker assemblies will aim to meet environmental standards, ensuring cleaner operations and reduced resource consumption.

Research and Development Initiatives

Continuous research and development will pave the way for new materials and technologies, further improving the performance and efficiency of OHV rocker assemblies in agricultural machinery.

9. FAQs

What is the role of the OHV rocker assembly in an engine?

The OHV rocker assembly controls the timing and operation of the engine's valves, ensuring efficient airflow and combustion.

How does an OHV rocker assembly improve fuel efficiency?

By optimizing valve timing and reducing friction, an OHV rocker assembly enhances combustion efficiency, leading to reduced fuel consumption.

What maintenance steps should I take for my OHV rocker assembly?

Regular inspections, lubrication, and timely replacement of worn parts are essential for maintaining an OHV rocker assembly.

Can I upgrade my existing machinery with a new OHV rocker assembly?

Yes, as long as the new rocker assembly is compatible with your machinery's engine type and specifications.

What are the signs of a failing OHV rocker assembly?

Signs may include unusual noises from the engine, reduced performance, and increased fuel consumption.

10. Conclusion

The OHV rocker assembly plays a pivotal role in modern agriculture, contributing significantly to operational efficiency and sustainability. By enhancing engine performance, reducing fuel consumption, and minimizing downtime, these assemblies are essential for the success of contemporary farming practices. As technology advances, the future of OHV rocker assemblies looks bright, promising even greater contributions to the agricultural sector. Investing in quality rocker assemblies and maintaining them diligently will ensure that farmers can meet the increasing demands of food production while operating sustainably and efficiently.

Previous

Next

Previous:

Next:

Recent News

Understanding the Importance of Piston Pin Bore in Agricultural Machinery

In the realm of agricultural machinery, the term "piston pin bore" refers to the cylindrical hole that houses the piston pin, which connects the piston to the connecting rod within the engine. This seemingly small component plays a pivotal role in the overall functioning of engines found in various agricultural machines, from tractors to harvesters. Understanding the piston pin bore's significance